LED Strip - Frequently Asked Questions

- ( The below information some comes from the Internet and professional websites.)

*** What does different LED means? Like 5050, 3528, 2835, 5730 ....

The abbreviation SMD refers to a 'Surface Mounted Device'.

That means this is an LED Chip (device) mounted directly to a light strip, without using wires.

The Numbers mean the dimension in unit milimeter. The LEDs are named by the dimension.

For example, 5050 means the width and length be 50x50 mircometer.

Different LED their spec. like brightness are different. Even the same code LED, their spec. are varied a lot.

The LED maker and provide the same code LED in different levels.

You cannot tell and compare the strip spec. by the same LED code, but need to look into the real data.

Usually Supplier will specify the LED strip spec. accordingly.

*** What LED chip are we use?

The LEDs on our LED Strip are from by an established (1996) Manufacturer in Taiwan called Epistar.

The LEDs have proved themselves to have a long lifetime and are

of very high quality, a lifetime of at least 50,000 hours can be expected.

Many of the cheaper LED Strips and Strips use LEDs which from the

outside look identical to the Epistar LEDs but they are cheap

copies with poor internal materials which give rise to a short lifespan. The

LEDs on these cheap strips are usually mounted to a very thin circuit board

with copper tracks which do not adequately dissipate the heat away from

the LEDs further shortening the lifetime of the product. Most of these LED

Strips are designed for short term use such as festival and holidays.

The cheap LED Strips can also have LEDs which are poorly graded

for color consistency so the color along the length of the same strip can

look very uneven, for example some LEDs may appear a different white

color to others which can look blue or warm white in color. For long term

use and professional installation our LED Strip is a much wiser choice.

*** What does CRI mean and why is CRI important in led lighting?

Can't tell the difference between the black and navy colored socks in your

walk in closet? Could be that your current lighting source has a very low

CRI! Not all light is made equal; some light renders color better than others.

Color Rendering Index (CRI) is the measurement of how colors look under

a light source when compared with sunlight. The index is measured from

0-100, with a perfect 100 indicating that colors under the light source appear

the same as they would under natural sunlight.

Full range of our LED strips are with CRI >95, presenting the true color for you.

*** What is the difference between CRI and Ra?

The calibration R1 - R15 color sample, is the R1- R15 color rendering and when a light source compared with reference standard light source, the index value is 100%.

The general color rendering index (Ra) is just calibrated R1-R8.

Color temperature is a way to describe the light appearance provided by a light.

It is measured in degrees of Kelvin (K) on a scale from 1,000 to 10,000.

Typically the white color temperature for commercial and residential lighting applications

fall somewhere on a scale from 2000K to 6500K.

About the CCT range, usually we follow below ranges:

Ultra Warm White: 2700K-3000K

Warm White (Soft White) : 3000K-3500K

Natural White (Neutral White) : 4000K-4500K

Pure White (Daylight White) : 5500K-6500K

Cool White ( Cold White) : 7000K-10000K

*** What is CCT shifting and how to control it?

All of the color temperature will be shift by any cover in front of the LEDs,different Glue

will have different influence on the whole temperature of LED strips.

For example, an bared strip light in 5000K, once be made into waterproof IP65/IP68,

the strip surface is covered by silicon gel or exposy gel.

The gel will lead the strip color temperature rise up to around 7000K (depends on the gel type).

Then the strip lighting looks bluish.

The lower temperature, the CCT shift is less. That means the warm white color will shift small range.

How to Control?

Way 1: To use a lower temperature LED to make the strip for a real CCT that you need.

For example, if you need 6000K daylight white in wateproof. Then can use the 4000K to make the strip.

But this method is hard to control the consistency each time and is not suggested.

Way 2: To use the special gel that already added yellow power in the gel, which makes the gel looks yellow.

Use this gel, the CCT shift amount is very negligible amount.

*** PCB color: the background of the FPCB color

Now we mostly do the strips with white PCB. If you need other colors ,we can also makethe PCB color with yellow and black.

*** Waterproof grade:

We can do different waterproof ways forthe LED strips for variable use:

*Non-waterproof : Bare Strip, with self-adhesive backing, for indoor or dry location use.

*Waterproof IP65 : Strip Surface is covered on top with Gel, and with self-adhesive backing.

IP65 grade can protect sprayed water from all direction.

*Waterproof IP67: The bare strip is put in a hollow silicone tube and sealed at two ends.

IP67 grade can shortly immersed in water.

*Waterproof IP68: The bare strip is put in a U Shape silicone tube, then covered on top with silicon gel,

and sealed at two ends, which make it's solid.IP68 grade can be used under water.

We have the CE RoHS certificate for the European clients and for some models also get UL/CUL listed for the American & Canada clients.

Yes, you can solder wire to any of the copper ports to connect strips together.

If I connect the strip backwards (+) to (-) and (-) to (+) will that ruin the strip?

No. LEDs are diodes so they only let power through in one direction.

Simply reverse the wires and the strip will work fine.

Can the strips be used in high temperature areas?

No. While LEDs are quite durable and will work great in most any

environment, heat is the main cause for shortened LED lifespan.

Therefore, the cooler you can keep the LEDs, the longer they will

last (if you can keep them below 80°C you should get the rated life

out of them). With this in mind, leaving them on for extended periods

of time while on the reel or bunched up in a confined space will

shorten their lifespan.

Can led strip and led strips be dimmed?

Yes, but this should be done by using one of our dimmers between the

LED Strip and the output of the Power Supply. It should not be dimmed

from a standard wall dimmer. If you want to use a standard wall dimmer to dim the low voltage LED strip, need to use compatible constant voltage dimmable power supply. Please contact us.

How many warranty years for the led strips?

We offer 1yr warranty for our premium led strips. During the warranty period, if any qualify fail please contact us for replacement.

What tape do you used in the led strips?

We have yellow and white 3M tape for the strips and also the Tesa tape to get

a strong viscous when paste inside the aluminum profile.

What is the series of the 3M/tesa tape used in the led strips?

Normally, we use 3M 300MP, Tesa 4965 in our led strips. However,

3M 200MP and VHB also available.

Which tape has the strongest stickiness?

Usually, the stickiness ranks as: 3M VHB>Tesa 4965> 3M 300MP.

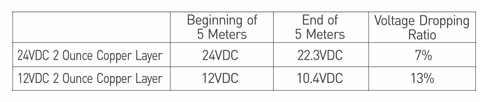

What is the voltage dropping?

Voltage is always dropping by transmitting of current decided by the

transmitting material and the size of material, Copper is the best

options to transmit current up till now.

How to decrease the voltage dropping?

a. Increase the thickness of Copper Layer to make the current transmit

quicker or bigger to improve the voltage dropping.

b. Using the electric way to boost the voltage at each section or boost

the current at each section, we are using constant current Triode and

constant current IC to improve the voltage dropping or make the

beginning and end of strips at the same brightness output.

c. Recommend the higher voltage input version instead of lower voltage

input version. 24VDC LED strips will definitely better than the 12VDC

strips at 5 meters run.

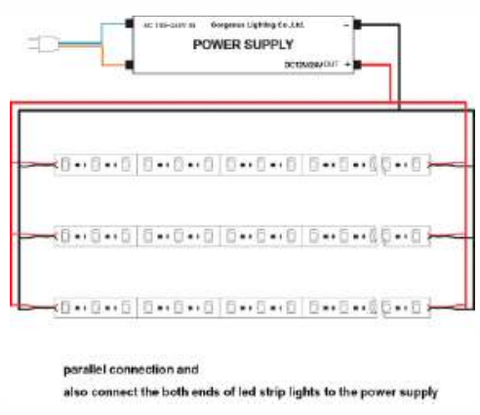

One is connecting the led strips in parallel, the other one is power the LED strips at both sides. Below connection drawing for your reference:

| 1)To connect the led strip lights in parallel | 2) Two side power in put in parallel |

|

|

Can the led strips be powered by 12/24VAC?

Most of the LED Strips we are manufacturing are working at DC version,

DC shorts for Direct Current, AC shorts for Alternative Current; There is

will be AC to DC converter or rectifier required if the existing power

source is AC output.

What kits options do I have?

According to the color, there are at least 6 options:

Single color kit, RGB kit, RGBW kit and color temperature adjustable kit, Addressable RGB color kit, and Addressable RGBW color kit.

Can I print my Logo on the PCB?

Yes, we can print your logo on the strips and the MOQ is 500M for one type

to print the logo, if the quantities is below 1000M, and we will charge US$100 for PCB redesigning.

There will be two ways to achieve the Logo Printing:

1. Laser Machine Carving:

We have the Laser Carving machine can do with the Logo on the PCB,

the Logo Color depends on the surface of raw material instead client

can choose the Color.

2. Silk Printing: we give the graphic file to PCB supplier to let them print

the Logo on the PCB, please confirm the Photo Clips from Supplier

before you move on with the final production, Black, White, Red Color is

the standard Ink in PCB supplier that can be used as the Logo Color,

Duo-Color of Logo will be complicated and require more time. Below is

the silk printing of UL logo FYI.

Width of PCB

For 3528 and 2835 strip, the range is 5/8/15mm.For 5050 strip, the range is 10/20mm.For 5630 strip, the rang is 10/12/13.5mm. For 335 and 3014, the range is 8/10mm.

Why the rated watts different to actual watts?

We are always using the rated watts on the label if our customer does

not specify that, which occur the confusion and misunderstanding that

customer complain the rated watts is not matching with actual watts

with too much difference.

The Rated watts are theoretical values calculated under ideal

circumstance. During the lighting fixtures are working, every component

of these fixtures have resistors, the resistors leads to voltage dropping.

We know P=U*I, when the voltage go down, the power go down to

Example: 2835 SMD 60 LEDs rated with 14.4 watts/M, when they are

driven by power supply at one ends, it will achieve 11-12 watts only, but

after 30 minutes lighted up, the current will increase after the whole

strip temperature raised up, results to achieve more than 12 watts, and

if the LED strips are lighted up with both ends ( to make the voltage

dropping less), it will reach the final watts at 13 watts/M, which is less

than 10% difference to rated watts is allowed.

Also we will reduce the current on some conditions, like when the strip

is glued, the heat dissipation is not good as naked, so we would reduce

the power to make sure the fixture do no generate much heat during

operation. Much heat will shorten the life of the LEDs.

What is the best ratio for blue and red?

Blue (wavelength: 455-465nm): is good for photosynthesis; and help to

induce Chlorophyll and Carotenoid, which are necessary for healthy

leaves.

Red (wavelength:660-665nm) : is the peak wavelength for photosynthesis

and photoperiodism. Red light is best for blooming and fruits.

What is difference between double sided PCB and single sided PCB of led strip?

LED Strip PCB is also the key to high quality but LED. Best double sided

PCB can bear large current, very good heat dissipation and has high stable

quality.

1. Flexible led strip PCB thickness

Double sided PCB of high quality led strip must have circuit on front sided

and backside; single side PCB don't have any circuit on the backside.

Different PCB thickness

2. Hand feeling

Without 3M Tape, you need to judge the led strip PCB quality by hands. The

double side PCB feel a little thick and hard and heavier than single sided

led strip; it feels very good quality. The single sided PCB feel thin, no weight,

very soft. it is easy to be blown by wind.

3. Circuit at backside

Double sided PCB of high quality led strip must have circuit on front sided

and backside; single side PCB don't have any circuit on the backside.

Different PCB thickness

The LED Strip Printed Circuit Board (PCB) is what electronically connects

electronic components. The quality and thickness of the copper is of very

important.

1. The thickness of the cooper PCB

The thicker the copper, the more current can flow and the more efficient

the strip is. currently in the market, it has 1 ounce, 2ounce, 4ounce thick

PCB.

2. The pureness of the copper

The more pure, the copper is the better. Higher quality copper means

less resistance and a stronger current.

3. Double sided and one sided copper

Copper PCB has double sided and one sided copper difference. double

sided cooper PCB is best.

4. Heat dissipation systems design of PCB

Only high quality LED Strip PCB has such design. High quality Printed

circuit Board will have a thin film at each side. it will improve the heat

dissipation of LED Strips. in the market, many factories reduce the cost

and use the one sided film.

You'll want to take each one of these factors into consideration when

selecting the provider of your Flexible LED Strip lights. Choosing the

wrong solution could end up costing you more than you might imagine